Silk, is an enchanting, pleasant, bright and beautiful material for weavers, has different types and textiles woven from fine fibers that you can wear to hard and heavy fabrics suitable for wall hangings and rugs. It has always been popular in many societies.

This very soft fiber is a protein fiber with an amino acid composition similar to human skin, it can absorb up to 30% of its weight without feeling moist. Silk clothing is perfect for summer and winter. Although its price has never been affordable. Silk is very suitable for both summer and winter although its price has never been economical.

Apart from economic considerations, the efficiency of a fiber for business purposes is determined according to properties like length, strength, flexibility, resistance to wear, elasticity, absorbency and different surface properties.

Its fibers are elastic meaning they stretch when pulled and return to their original length partially or completely after the tension is removed.

Silk thread is a fiber produced by some types of worms that make cocoons to protect themselves.

A cocoon pierced by a silkworm

In fact, silk is a fibrous protein that is spun from the mouth of a silkworm insect in the form of a thread. This insect weaves silk around itself and makes a silk cocoon and stays inside until it becomes a butterfly. To prevent any damage to the silk fiber and for cocoons to be suitable for silk weaving, the silkworm is suffocated by heat or hot air so that the cocoons are safe when they are extracted.

After suffocating the worm, cocoons are opened and continuous silk fibers are obtained, which may reach hundreds of meters each. Keep in mind that silk is famous because it’s difficult to work with. Fine threads can be slippery and silk fabric requires subsequent washing with special care during work.

Cultivation of silkworms

History of silk weaving:

Using natural fibers for textile materials has begun before recorded human history. The oldest indication of using fiber is probably the discovery of linen and wool cloths in the excavation sites of the inhabitants of Lake Switzerland (7th and 6th centuries BC). Several plant fibers were also used by prehistoric humans. Hemp is probably the oldest fiber plant cultivated in Southeast Asia, then spread to China.

The art of linen weaving and spinning was well developed in Egypt by 3400 BC, indicating that linen was cultivated before that date.

The production of silk and silk products originates from the highly developed Chinese culture. The invention and development of sericulture (cultivation of silkworms to produce raw silk) and silk spinning methods date back to 2640 BC.

The origin of silk production and weaving is obscure and mythical, but we know that this industry undoubtedly started in China. Silk weaving became a major industry and one of the main China’s exports during the Han Dynasty. The caravan route across Central Asia, known as the Silk Road, carried Chinese silk to Syria and Rome.

In the 4th century BC, Aristotle, the Greek philosopher, mentioned that sericulture was practiced on the island of Kos, but apparently this art disappeared and again spread from China to Turkestan in the 6th century AD.

Silk was used by rulers as diplomatic gifts and also to buy off threatening nomads and weaken them by giving them a taste of luxury. Around 1400 BC, sericulture and silk had spread from China to India.

Silk road

Silk weaving and dyeing were gradually recognized as handicrafts in Syria, Egypt, Greece, and Rome. Workers obtained raw silk from East Asia and most of their yarn was obtained by spinning silk fabrics from the East. Silk culture remained an Asian mystery.

Finally, raw silk was in high demand in the Mediterranean region. Justinian I, the Roman emperor from 527 to 565 AD, convinced two Iranian monks living in China to go back there to smuggle silk worms in the gaps of their bamboo sticks to Constantinople (current Istanbul, about 550 AD).

The culture of using silk flourished in Europe for centuries, especially in Italy and France (from 1480). But in 1854, the devastating silkworm plague appeared. Louis Pasteur, who was asked to study the disease in 1865, discovered the cause and invented a means to control it. This industry recovered in Italy, but not in France. Meanwhile, Japan was innovating new silk weaving methods and soon supplied a large portion of the world’s raw silk.

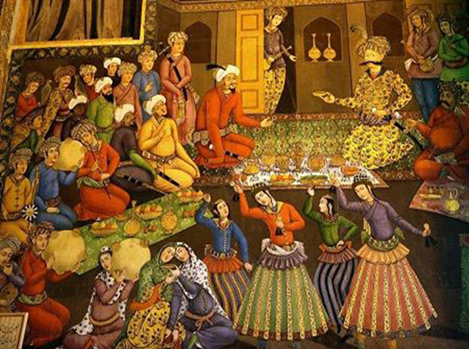

In the second century AD India sent raw silk and silk fabrics to Iran (Japan also acquired and developed the science of silk production a few centuries later). During the Parthian period (247 BC -224 AD), Iran became a center for trading silk between East and West. Meanwhile, the import of silk like other foreign goods became popular in Iran and reached its peak in the Safavid era

The stunning example below, is one of thirteen scenes of Safavid courtiers and their captives, nobles, women and Georgian children, captured during four campaigns between 1540 and 1553.

Silk weaving, Safavid dynasty

Silk weaving materials and instruments:

Instruments: silk weaving weaving loom

The loom consists of several parts and is installed in two fashions, which are ground and surface.

Loom components:

- Navard: a cylindrical wood with a diameter of 15 to 20 cm and a length of 132 cm, that is placed on two wooden bases. Its function is to strengthen the silk thread and spin the woven fabric around it and align the threads for weaving. You must secure the roll to the ground with wooden pegs.

Navard turning wood: It is one of the components of the loom. The stick with which navard is turned.

- Base: The loom has six wooden bases, including two bases in front and back, to tightly hold the weaving threads, two bases to hold the navard and two bases to connect the pedal to the ground.

- Comb: a wooden tool with wooden or metal teeth that is made in 48 cm x 20 cm dimensions. The comb is used to beat the threads tightly after the weft passes through them.

Weaving loom

- Spool: a tool that is located on the top of the shuttle in a double form. The spools should be connected to the framework of the loom by a thread on one side and to the gourd on the other side. Its task is to regulate the shuttle. Their length is 22 cm and their width is 6.5 cm and they are completely made of wood.

- Pedal: the pedal must be wooden. This piece is similar to the car pedals and is located at the bottom of the loom. With the pedal, the threads are connected to the ground on one side and to the spindle on the other. The pedals are double with the weaver’s foot is placed on them. Their function is to pull the shuttles down, and most of them are 27 cm long and 9 cm wide.

Small loom

- Spool pin: wooden device inside which the bobbin is placed and passes the weft between the threads. Its outer size is 28 cm x 5 cm and its inner part measures 13.5 cm x 14 cm.

- Small bobbin: The small bobbin is made of reeds and weaving threads (wefts) are wrapped around it and placed inside the spool pin for weaving. Its length is 7 cm and its diameter is 1.5 cm.

- Big bobbin: its length is 10 cm and its diameter is 2 cm. The thread is wrapped around the big bobbin.

- Shuttle is made from a combination of three reeds and cotton threads. Its length is 57 cm and its width is 18 cm. It is connected to the spools from the top and to the pedal of the machine from the bottom. Its function is to raise and lower the knitting threads to pass the weft. In order to wrap the threads inside the bobbin, they use a device called a wheel.

Weaving tools

Necessary materials for silk weaving:

- Warp thread is made of silk in 4 or 5 layers. Usually, silk weavers prepare warp thread from silk cocoons that they grow themselves. Otherwise, it must be bought from the market.

- Double weave silk: which is called bafe in the local language and is used as a weft.

- Golden and silver threads: used for decoration as a weft.

- Dye: natural dyes were used locally in the past (runas, walnut skin, pomegranate skin, etc.) and chemical dyes (blue, black, red, and green) used for dyeing threads.

dyed silk fibers

Different challenges

Following the developments in the transportation and communication industries, the highly localized skills and arts associated with manufacturing and the textile industry were transferred to other countries and upgraded in response to local needs and capabilities. New fibers were also discovered and their use was researched. In the 18th and 19th centuries, the Industrial Revolution encouraged mechanization in processing various natural fibers, leading to an amazing increase in fiber production.

The introduction of regenerated cellulosic fibers (fibers made from cellulosic materials that have been dissolved, purified, and extruded) such as rayon, followed by the invention of fully synthetic fibers such as nylon, challenged the monopoly of natural fibers for textile and industrial applications. All kinds of synthetic fibers with desirable and special properties began to penetrate and dominate markets that were previously monopolized by natural fibers such as silk weaving.

Identifying the competitive threat from synthetic fibers led to intensive research that was directed towards breeding new and better strains of natural fiber sources with higher performance, improving production and processing methods, and modifying the properties of fiber yarn or fabric. Significant advances have made it possible to increase total production, although the actual market share of natural fibers has been reduced by the influx of cheaper synthetic fibers that require fewer working hours to produce.

Uses of silk products:

Among the uses of silk are the edges of the collar, cuffs, and shirtfront of luxurious traditional clothes. Their raw material is dyed pure silk fibers, vegetable or mineral colors and silk gives a special polish to the colors and patterns after weaving.

Silk dress

Identifying the genuine silk

Recognizing at a glance how to distinguish genuine silk from fake silk requires practice, but here we introduce you to tips that are used all over the world.

- Look for the shine. Genuine silk because of the molecular structure of its threads reflects light in a unique way, meaning it shimmers and its color changes as light travels across it, whereas fake silk only reflects white light.

- Rub the fabric between your fingers. Pure silk is a natural fiber and reacts differently compared to synthetic fabric when rubbed between your fingers. After a little rubbing, you should feel it warming up. In this case, your fabric is definitely authentic.

- Real silk fabrics pressed together create a distinctive sound that some describe as stepping on fresh snow. So listen to this sound carefully. Yes, it is definitely the first time that you should pay attention to the sound of the fabric.

- Pure silk does not mean 100% silk as the fabric only needs to contain 95% or more silk to be known as the pure silk. Any fabric whose silk content is between 20 and 50% can be called a silk blend or mixed silk. However, these standards are not always monitored carefully, so make sure you buy your clothes from reliable sources that are known for producing quality pieces of silk.

How to maintain silk products:

Knowing how to maintain, wear and wash silk clothes will help the longevity of your silk. In summary, silk textiles should be protected from continuous moisture, direct sunlight for a long time, bleaching chemicals and sharp objects. If you look at silk products as an investment, you can definitely use them for more than just one season.

Use mild detergents to wash silk clothes. Use powders and detergent liquids that are suitable for delicate fabrics. Do not use hot water to wash silk clothes because hot water makes them shrink. Be careful that strong detergents and cleaners such as bleach are not recommended at all because these substances cause irreparable damage to fabric fibers.

The best and safest way to wash and clean silk clothes is to wash them by hand, unless the words “dry cleaning only” are written on the clothes, in which case the washing method is clear.

Author and compiler: Najma Shahmohammadi